Industry 4.0

Tailored support for Industry 4.0 projects

Serving you

Imagine a flexible, robotised and automated factory, a digitised factory using IoT, information systems and big data to optimise operation and prepare for future developments. Our mission is to act as an integrator, assembling the subsets of solutions that will comprise your production system while guaranteeing its performance and that of its components.

An effective response

- Express your needs and construct your projects

- Make your project part of an industrial ecology policy: establish links with other partners, recycle waste, share services and buildings, build a local smart grid

- Provide you with utilities, a framework and work tools so that you can focus on your processes

- Design, build and operate an nimble facility that can adapt to your needs

- Robotise and automate your utilities, your processes and your buildings to make your facility safe and efficient

- Digitise your processes to optimise and remotely control your industrial facilities

- Provide a single contact point for managing the building and utilities

- Support change management by training your people

Thinking up solutions together

Four innovative approaches to harness all the potential of Industry 4.0 :

Advice 4.0 to optimise, modernise or build a facility

- Help to express your functional requirements, financial needs and expected performance targets by bringing the best international standards to bear

- Set up a technical and financial consortium capable of designing, building and operating your facilities

- Provide detailed visibility of the costs of building, maintaining and operating the future facility and identify the best locations for it

- Offer suggestions for improving operational performance and help to manage change

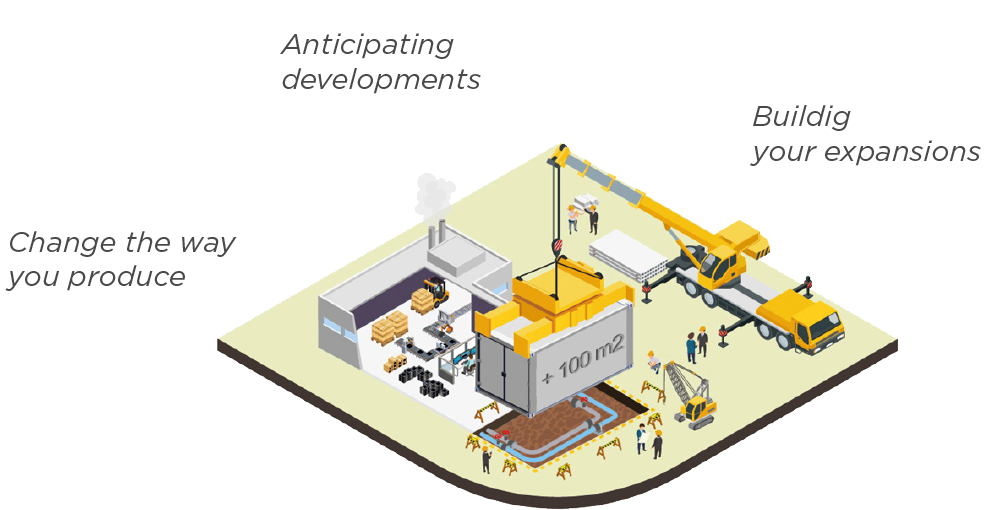

Defining a flexible factory together

Making industrial processes more flexible is a major factor in adapting nimbly to changing demand. Available solutions include modular buildings and reconfigurable production lines in order to adapt the volume and nature of output to orders. Together, we can create the conditions to improve responsiveness. How?

- From the design phase, we can anticipate how the facility might evolve throughout its lifecycle

- We can build a modular, reconfigurable, scalable facility that anticipates changes to the nature of production

- We can support your people in the use of new tools and new forms of organisation

- We can limit the depreciation of your property assets by ensuring the capacity for swift adaptation at the lowest cost and simplifying compliance upgrades

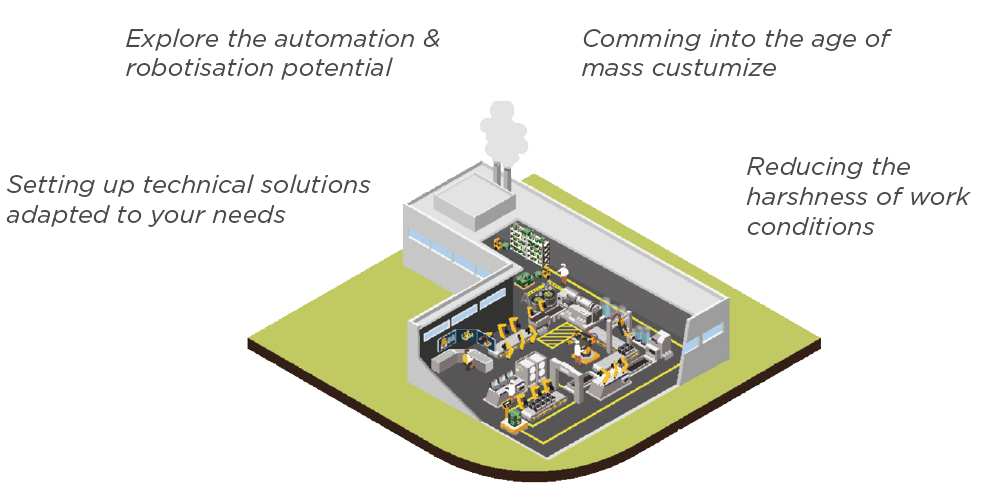

Developing a robotised and automated factory

Central to Industry 4.0 projects, robotics, cobotics (especially in the automobile industry), internal logistics and robotic palletisation (especially in the logistics industry) are synonymous with lower costs and higher productivity. How can we make best use of these opportunities? By:

- Carrying out an audit of the facilities you want to robotise or automate

- Defining functional requirements for the construction of a new facility

- Identifying the best technical solutions according to your functional requirements and performance targets: lower costs, fewer workplace accidents or musculoskeletal disorders, etc.

- Carrying out the design, adaptation and integration phases for solutions involving robotics, cobotics, automation or additive manufacturing

- Helping to manage change

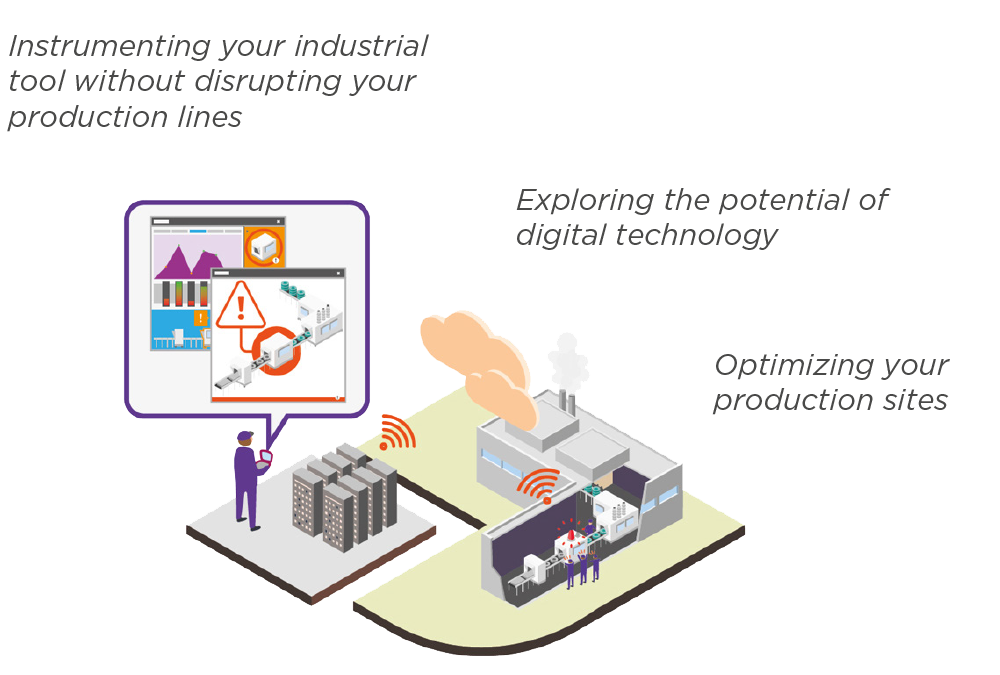

Designing a digitised factory

In order to increase productivity we can harness all the potential of automated production, equipment traceability, mobile data access, big data, 3D printing and M2M technologies. The benefits include fluid, digital reporting, a paperless company, real-time performance management, data security and protection. How can we achieve this? By:

- Using BIM (building information modelling) to create a digital twin of your factory and facilities

- Implementing technical solutions to capture, store and analyse data: IoT, data storage and security, big data and predictive analysis

- Guaranteeing the monitoring of operations and the remote control of facilities by means of predictive maintenance, hypervisors and connected operators

- Using operating data to generate proposals for improvements, such as the centralisation and safeguarding of information, cost reductions, quality optimisation and the limitation of downtime

Targeted support in the field

With the strength and experience of a major group operating in over 30 countries, we can harness all the skills and expertise needed to bring your project to a successful completion:

- the support of the Bouygues group in areas such as property development, engineering and construction

- the financial strength of a global Group

- a global operational and support capability

Dedicated "Industry" business units in France, Great Britain, Ireland and Canada.

One community of 1.500 people dedicated to your every need in design, engineering, execution and industrial maintenance.

An engineering department focuses specifically on industrial maintenance contracts:

- start-up engineering: master plan, quality assurance plan, safeguarding plan, shared management tool, indicators

- computer-assisted maintenance management: installation and parameter setting

- Lean Micro Innovation, FMECA, obsolescence studies, failure analysis, feasibility studies, etc.

- skills management: e-learning, assessment

For your industrial project, we seek out and implement the best available new technologies for even better performance, by:

- using BIM technology to improve productivity,

- studying the impact of IoT to optimise your maintenance,

- using Lux services to reduce your energy consumption

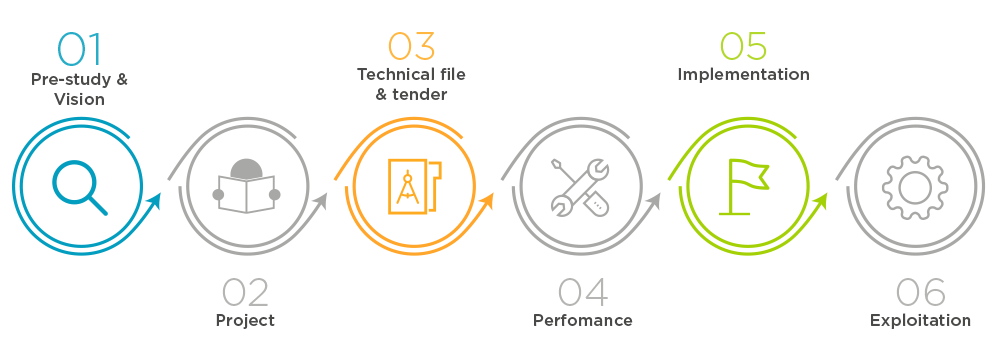

Together we define your 4.0 factory of the future with a rigorous methodology…

We guarantee you the framework of a trust-based project approach:

Our commitments

- Requirement

Compliance with your safety/security standards: authorisations for working on all your installations.

- Certification

Obtaining ISO 9001 and 14001, OHSAS 18001, Qualifelec, Qualifoudre, APSAD, MASE, ATEX, BREEAM and HQE certifications.

- Safety

Staff and subcontractors: safety day, audit and risk analysis, making work areas secure.

- Availability

With a dense network of locations, we are a truly close partner who is responsive and listens to you.

Discover also

A full-service offering for your industrial projects, with dedicated solutions

Take advantage of our engineering, works and maintenance expertise to modernise your production facilities. We support you in your project from the outset, helping with administrative formalities and the financial package.

Our latest case studies

Latest news

Find all the topics that make Bouygues Energies & Services news: projects, innovations, public and client events, partnerships, press releases ...

- One of the largest photovoltaic power plants in France is being built by our teams.Sustainability is a unifying theme and major partnerships are being established.Our UK team has been selected by VIRTUSfor the turnkey delivery of its LONDON7A day of interactive discussion about diversity and inclusion strategy.Round table to discuss about national and European support for the hydrogen industry.Project Manager Aaron Yule will lead the team in charge of transforming Ashford's lighting.Official opening ceremony of the new North Mole thermal power plantAfter 1 year of work, the connected control centre of the OnDijon project was unveiledBecause preserving health and safety is and will remain the top priority.The Top Employers Institute acknowledges the quality of the company’s working conditions and its HR policies.Come and meet us to develop innovative energy solutions togetherHow is the OnDijon scheme progressing after one year ?The results of more than 3 years of work presented at the European Utility WeekThe international event on urban development.A successful handover had been completed for Phase 1 of VIRTUS Data Centres’ LONDON5 facility.

With Sun'R we have combined our skills to support Lamagistère in its energy transition.Axione becomes the 86th member of the altnet cooperative.Our goal : being innovative together.We will demonstrate that it is possible to put technology at the service of well-being!SIRO announces investment with joint venture to connect 10 towns to Its gigabit networkSmart management of public amenities will enable local authorities to improve their performance.

Mozambique faces electricity supply challenges due to limited infrastructure required to generate and evacuate power.Signing of a new contract with Equis, the first regional developer of renewable energiesAward for centralised technical management system of Marseille’s L2 bypassThe safety commission met on site and officially recommended that the building could open to the publicDelivery of 4 solar farms 100km to the north of BangkokNew latest-generation production site for a world leader in carbon fibre manufacturingAn exemplary project combining technical challenges, energy development and local involvementThree key aspects of the airport: operations centre, baggage and pass officeCreation and animation of dynamic trail of light showcasing 39 important sitesContract signed with Equis, leading developer of renewable energy in the region